OPTIONS FOR INJECTORS

This glossary serves as a concise guide to the options available for our filling injectors. It facilitates understanding of key terms and assists you in selecting the appropriate option for your requirements.

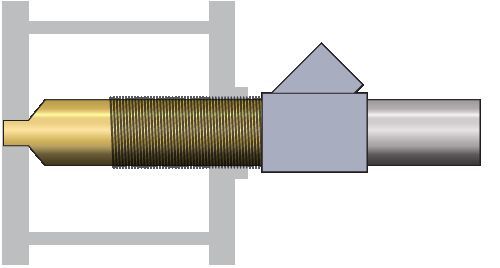

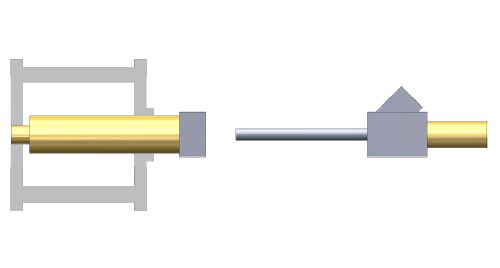

THREADED BARREL

A male thread on the barrel allows precise adjustment and fixation of the injector in its depth position. Additionally, it prevents axial displacement of the injector. For this function, appropriate clamping flanges are required

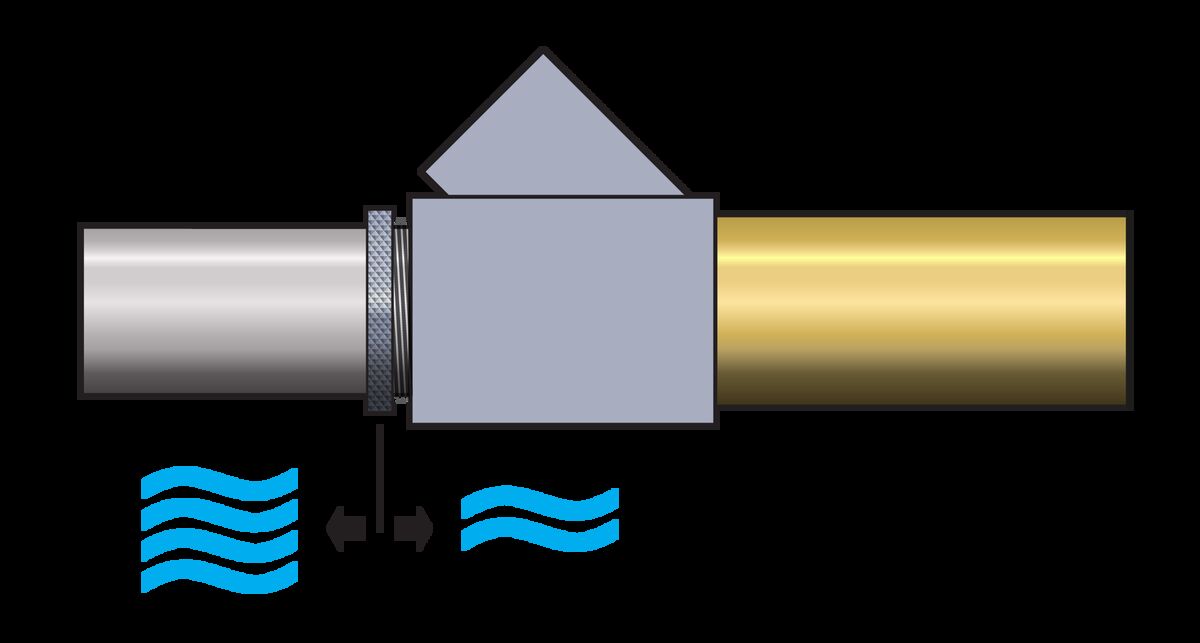

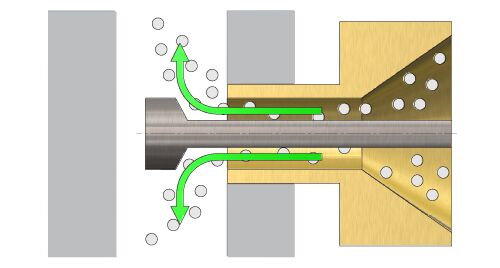

ADJUSTABLE FILLING AIR

This option allows the performance of the venturi nozzle in the filler to be adjusted. As a result, suction power, air consumption, and thus the filling behavior can be individually adjusted.

CONTROL

For injectors with two air connections, the fill air is also used as control air to open the injector. A separate control connection allows the injector to close. If fill air and control air (open) are to be separated, three air connections are required.

CYILINDER SEALS

Sleeves are inexpensive and easy to replace. Glide seals have a longer service life but require more effort to replace. Their initial cost is higher compared to sleeves.

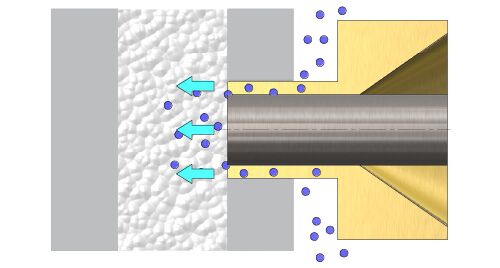

VAPORIZING OPTIONS „BED“

A core vent integrated into the plunger tip of the injector enables vaporizing directly at the filling position. Additionally, vaporizing can also be applied via the external contour of the tip. This featureis implemented as a standard in many of our injectors

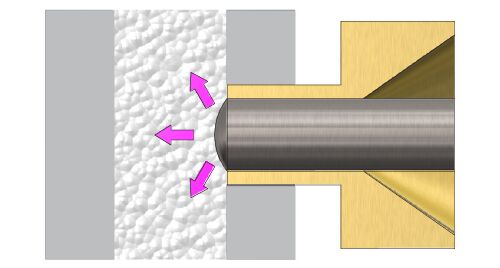

RAISED DESIGN „BOM“

A raised design of the plunger compresses the particle foam at the injector position inside the mold. This results in improved adhesion between individual beads. Also, this prevents bulging in expanding material.

EJECTOR FUNCTION„AW“

Injectors with integrated ejector units save space. The ejector can be operated pneumatically or mechanically via an ejector rod extending from the filler. The maximum stroke can be selected.

OPENS INTO THE MOLD „NV“

Coated tools and sensitive mold surfaces are protected by a filler that opens into the mold. The plunger is designed to laterally deflect the beads during the filling process.

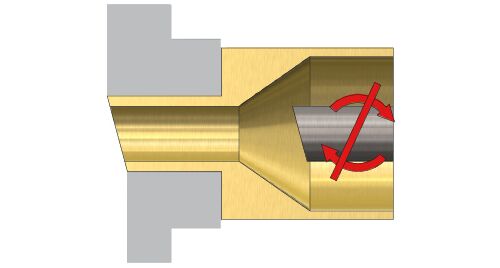

NON-ROTATING PLUNGER „VG“

For complex mold geometries, it may be necessary to adapt the front end of the injector to the mold shape. The rotation-locked plunger enables this by preventing the plunger from rotating, using a positive (form-fit) locking mechanism.

QUICK CHANGE FUNCTION

Divisable injector systems help to minimize setup and downtime. Fillers with a quick-change function consist of a barrel and a drive unit. The barrel typically remains in the mold, while the drive unit can be removed with minimal effort and reused on another tool.

CYCLE COUNTER

A cycle counter allows users to view the actual number of operating cycles performed by an injector at any time. The counter is integrated into a cylinder cap and mounted on the control cylinder of the injector.

Kröner is a family-owned, globally operating company specialising in the production of core vents as well as in the development and manufacturing of innovative solutions in the field of injector technology.