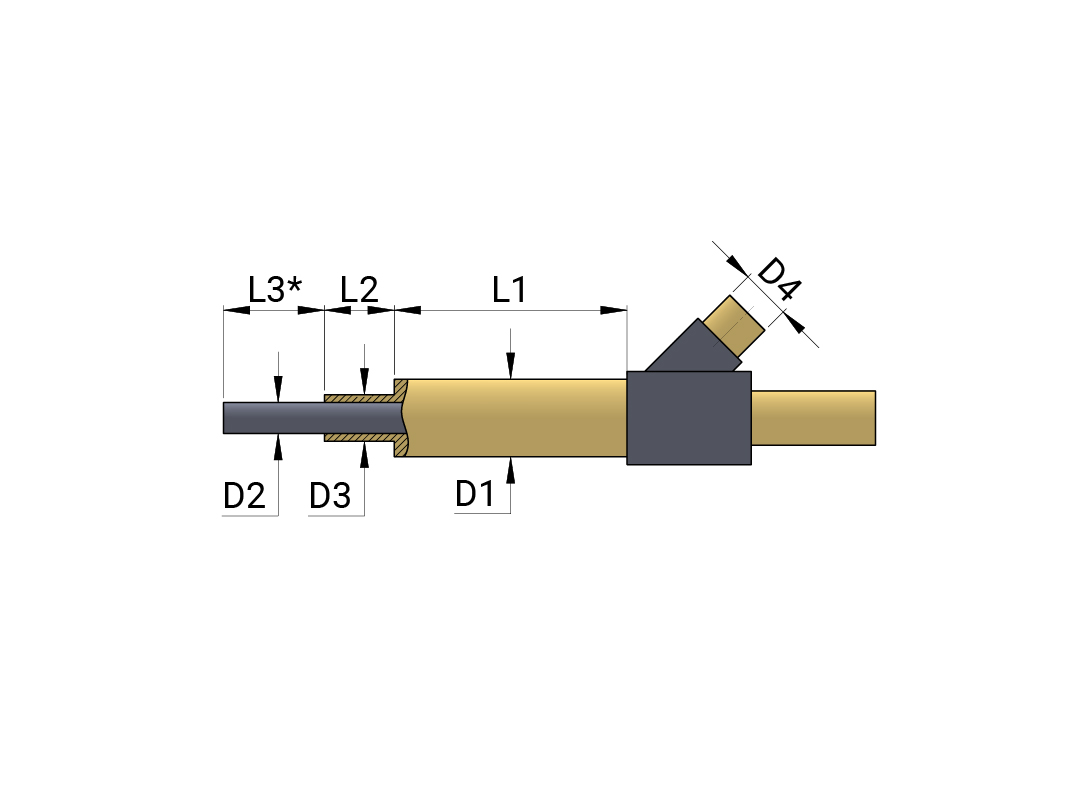

This glossary serves as a concise guide to the options available for our fill-injectors. It facilitates understanding of key terms and assists you in selecting the appropriate options for your requirements.

KRÖNER FILLING TECHNOLOGY MODULAR, RELIABLE, EFFICIENT.

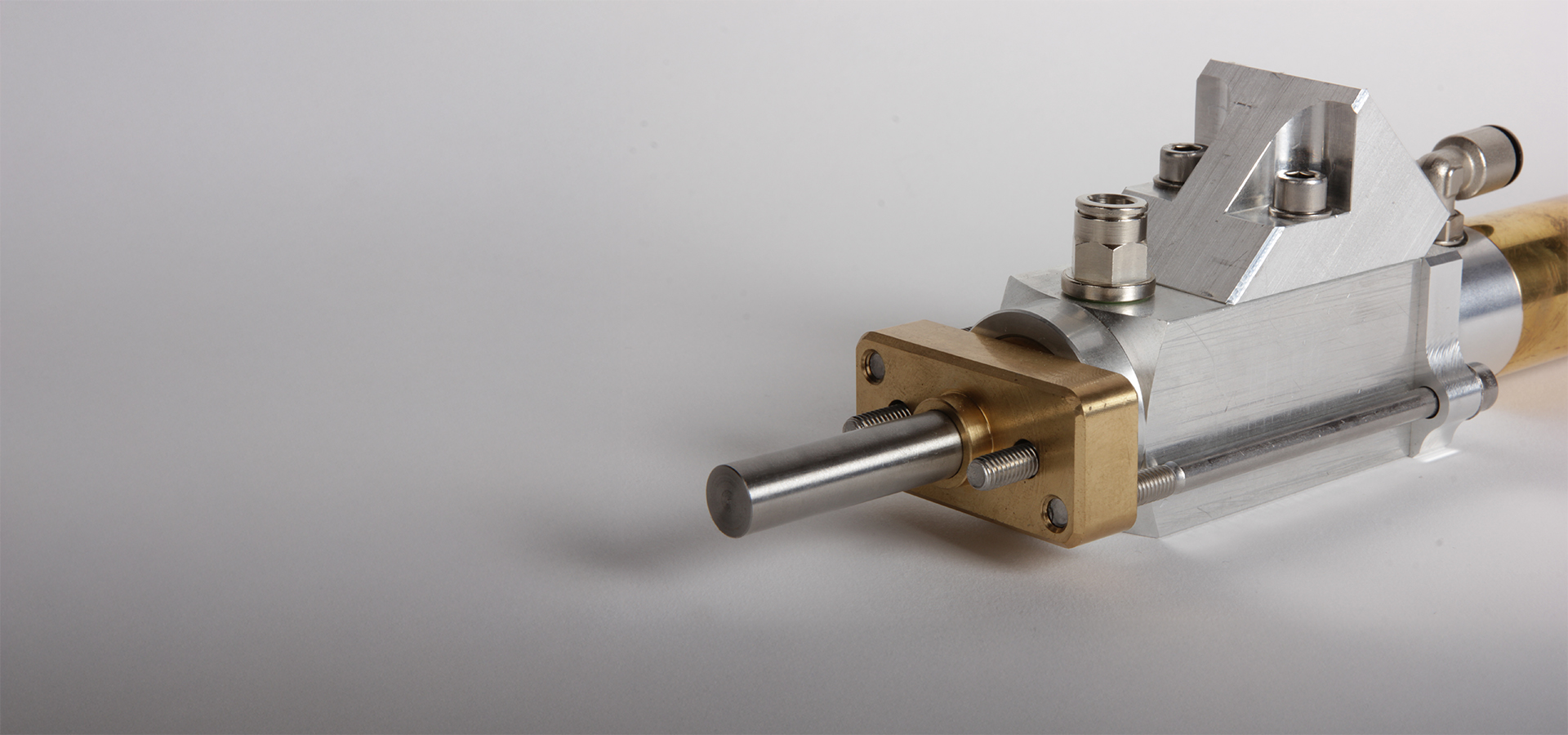

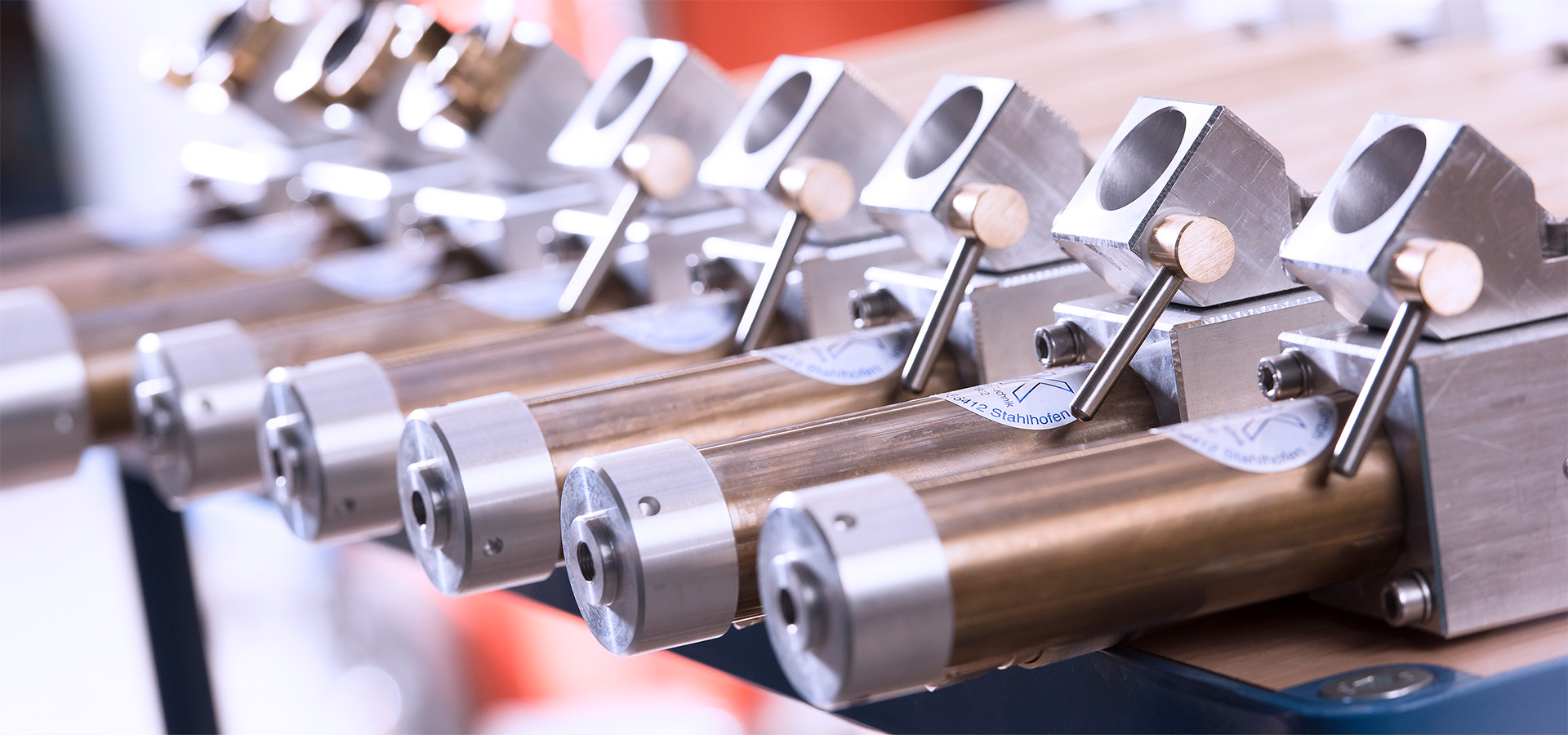

The term “Filling technology” refers to all product-side components required for the controlled feeding of particle foams into the mold. These include injectors in various designs, material connections, fluidizing nozzles, silo components, and associated accessories. These components are essential to the foaming process and play a crucial role in process reliability, repeatability, and product quality. Our in-house developed and manufactured injectors feature a modular design that allows them to be precisely tailored to customer-specific requirements. From just six base models, more than six million possible variants can be configured - ensuring maximum flexibility while maintaining consistent standardization. The accurate selection and combination of these components not only ensures stable filling but also enables efficient maintenance, short setup times, and high system availability.

Kröner is a family-owned, globally operating company specialising in the production of core vents as well as in the development and manufacturing of innovative solutions in the field of injector technology.