INTEGRATES EJECTOR SYSTEMS

In integrated ejector systems, the injector’s piston rod can assume three positions: injector open, injector closed, injector extended to the front (ejection). The most common reason for using injectors with an integrated ejection function is limited space on the mold or the wish for pneumatic ejection. We offer various designs that can be selected based on the machine control system, the number of injectors on the mold, and the geometric characteristics of the molded part

ACTUATION OF THE EJECTOR FUNCTION

The ejector plunger of the injector can be actuated in two different ways, depending on the ejector system:

1. Mechanical actuation: In this case, the rod extending from the rear of the pneumatic cylinder is actuated like a conventional ejector via the ejector plate.

2. Pneumatic actuation: Here, a pneumatic signal from the machine control system actuates the ejector cylinder.

ADVANTAGES AND DISADVANTAGES OF BOTH EJECTOR ACTUATION METHODS

Mechanical actuation is easier to integrate into the production process, as the ejector speed can be directly controlled by the machine control system. If the ejector extends too quickly, it may damage the molded part and cause it to become misaligned during demolding. This risk is especially relevant when the part is not a flat plate geometry or when multiple injectors are used per cavity. In such cases, mechanical actuation is recommended. For flat parts, pneumatic actuation can offer a cycle time advantage over mechanical activation. Additionally, no ejector plate is required in this setup

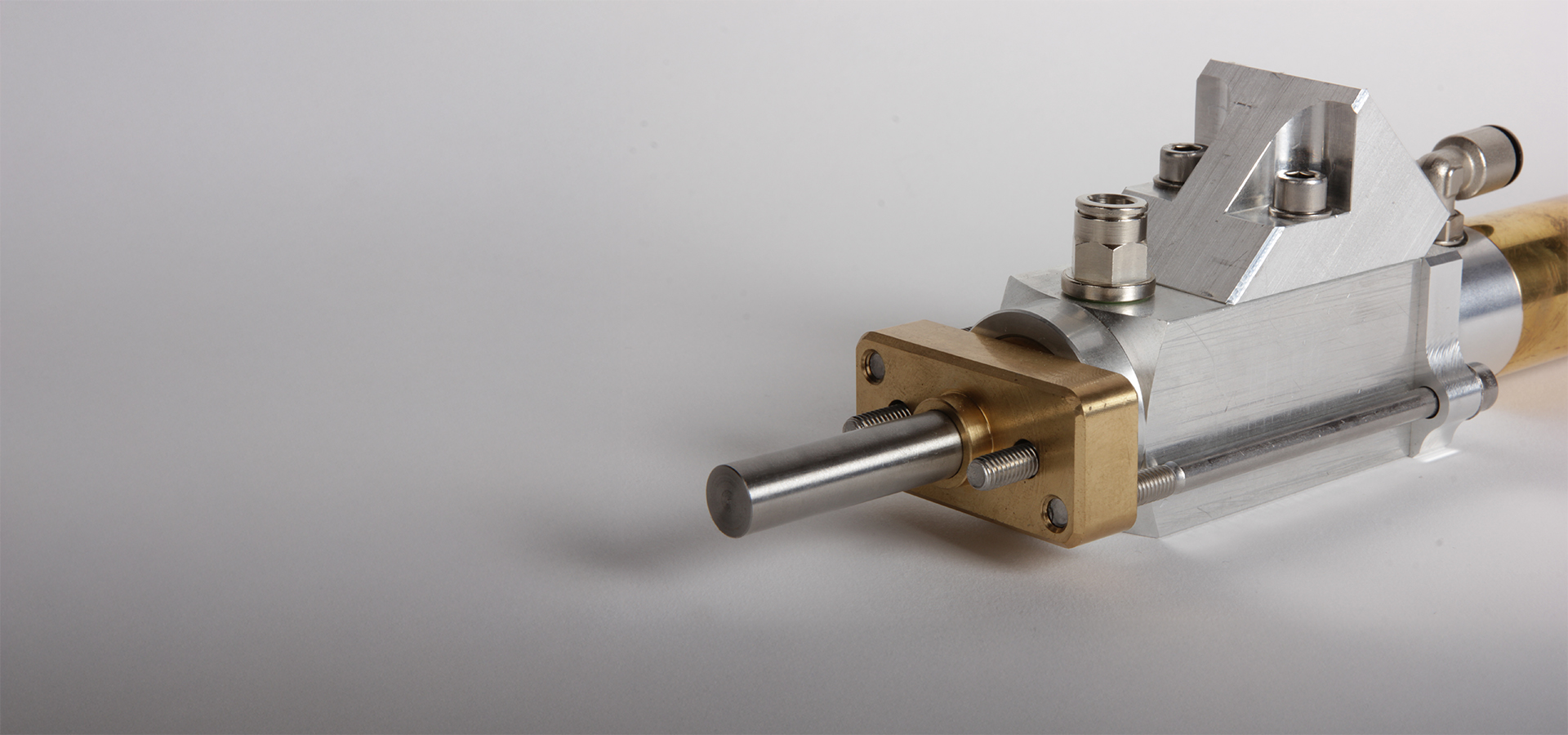

PNEUMATIC-MECHANICAL COMBINED EJECTOR (TYPE AW)

Currently our best-selling system, as it can be used on almost all machines without additional signals thanks to its simple control. Available for the following injector types: KSW, K1-50, KSW-K, EURO-SE, EURO-SN. Suitable for a wide range of applications.

ADVANTAGES

- Simple control (With mechanical actuation of the ejector, no additional machine signal is required. Any machine with two signals can operate it.

- Optionally, the cylinder can be converted from mechanical to pneumatic actuation with minimal effort. However, this requires an additional signal for ejection.

- The mechanical actuation works similarly to conventional methods using ejector rods.

DISADVANTAGES

- With mechanical actuation, the machine must work the ejector plate against the air pressure inside the pneumatic cylinder. The resulting force is significant and can cause issues when multiple injectors are installed on the mold tool

- The cylinder design is relatively complex, making assembly and maintenance more demanding.

- If pneumatic ejection is used, the following applies: as with all pneumatic cylinders, it is diffi cult to operate them synchronously. Variations in hose lengths and uneven wear can cause the cylinders to extend at different speeds.

- This system is only available for plunger diameters up to 20 mm.

Pneumatic control

Mechanical control

MECHANICAL EJECTOR (TYPE AWII)

The ejector is actuated via the ejector plate. However, during the cycle, compressed air must also applied to the ejector cylinder and then selectively switched off when ejection is required. The machine typically requires the following connections: Open/Close and Ejector ON/ Ejector OFF. This system is still relatively unknown but offers notable advantages over the combined ejector. It is currently available for the following injector type: K1-50 AWII, and in principle can also be implemented on other filler types. Highly suitable for deep components.

ADVANTAGES

- Simple cylinder design allows for quick assembly and maintenance.

- During ejection, the cylinder is unpressurized, allowing the machine to actuate the integrated ejector rod effortlessly.

- Also suitable for larger plungers, up to D2 = 30 mm.

- Shorter total length compared to the combined ejector type AW.

- A variant with continuous piston rod enables very long ejection strokes with very short cylinder body lengths (e.g. barrel L1 = 150 mm, ejector stroke L3 = 330 mm).

DISADVANTAGES

- In addition to the signals for opening and closing the fi ller, a signal for the ejector air is required.

- This signal must remain active continuously until the moment of ejection.

MECANICAL CONTROL

PNEUMATIC EJECTOR (TYPE AWIII)

The ejector is actuated via a pneumatic signal. Similar to the mechanical ejector (type AWII), compressed air must remain applied to the ejector cylinder throughout the cycle and is switched off when ejecting is required. The machine must typically be equipped with the following connections: Open/ Close and Ejector ON/ Ejector OFF. Due to its design, this variant is only suitable for small plungers (max. plunger diameter D2 max. 12 mm). Currently available only for the following injector type: EURO-SN-AWIII. Well suited for fl at components, such as sun visors.

ADVANTAGES

- Simple cylinder design allows quick maintenance.

- Can be used on machines without an ejector plate.

DISADVANTAGES

- Only available as a pneumatic ejector, typically only with short strokes.

- Low closing force, therefore suitable only for small plungers (D2 max. Ø12mm).

- Besides the signals for opening and closing the fi ller an additional signal for ejection air is required. This signal must be continuously active until ejection is required.

Pneumatical control

Kröner is a family-owned, globally operating company specialising in the production of core vents as well as in the development and manufacturing of innovative solutions in the field of injector technology.